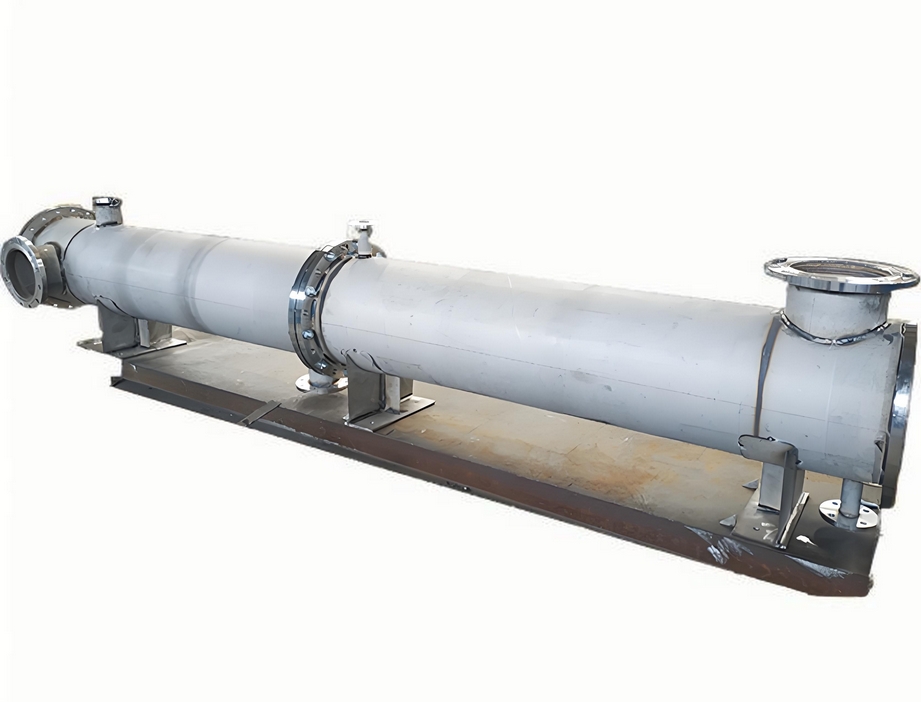

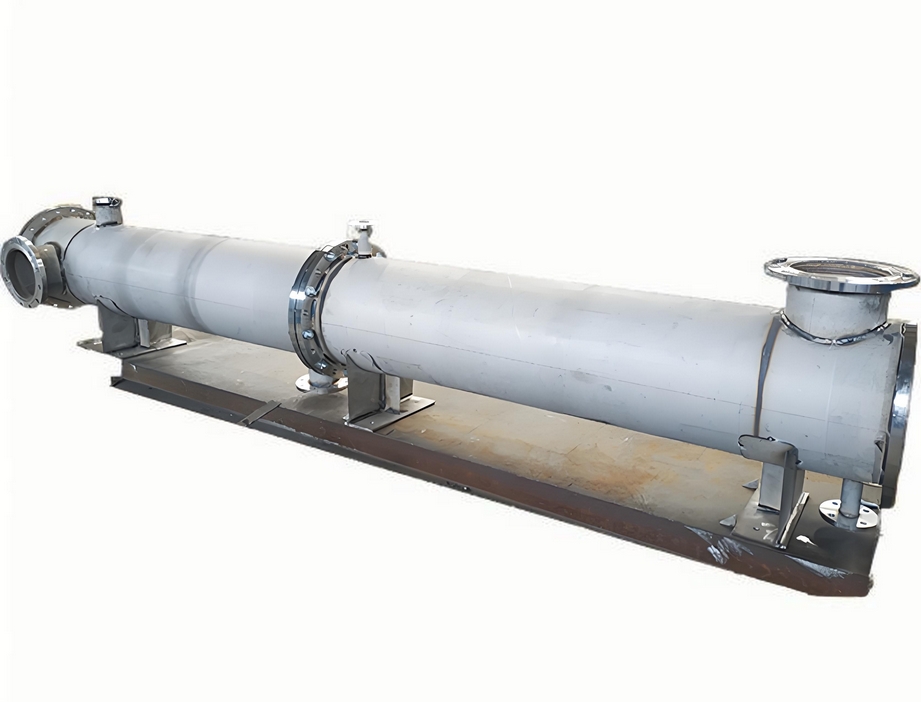

The Industrial Water-Cooled Condenser is a cornerstone of industrial refrigeration and heat management systems, designed to reject heat efficiently in applications requiring precise temperature control. Its primary function is to condense gaseous refrigerants into liquids by transferring heat to a water stream, enabling continuous cooling cycles.

Key Features & Benefits:

High-Efficiency Heat Transfer: Optimized tube-and-fin designs ensure rapid thermal exchange, reducing energy consumption by up to 30% compared to air-cooled alternatives.

Corrosion Resistance: Electropolished stainless steel shells and copper alloy tubes resist chemical degradation, extending lifespan in harsh environments (e.g., saltwater exposure).

Global Compliance: Certified to ASME, PED, and CE standards, ensuring seamless integration into international projects.

Scalability: Modular configurations support capacities from 50,000 to 5,000,000 BTU/hr, adaptable to factories, data centers, and cold storage facilities.

Why Choose Us?

Cold Storage Expertise: Engineered for -40°F to 122°F operating ranges, ideal for frozen food warehouses and pharmaceutical cold chains.

Eco-Conscious Design: Compatible with low-GWP refrigerants like R744 (CO₂), aligning with global carbon reduction targets.

"Optimize your industrial cooling today—request a custom thermal analysis and quote."

Heat Transfer Mechanism: Forced-convection cooling with helical baffle technology to minimize pressure drop.

Material Innovations:

Shell: 316L stainless steel (marine-grade corrosion resistance).

Tubes: Admiralty brass (90/10 copper-zinc alloy) for enhanced deionized water compatibility.

Efficiency Metrics:

Heat Rejection Rate: 10–150 kW per module (ASTM E1225-certified).

Water Flow Rate: 5–500 GPM (adjustable via bypass valves).

Refrigerant Compatibility: Optimized for R744, R134a, and R513A, with proprietary lubricant compatibility testing.

Installation Checklist:

Site Preparation: Ensure level concrete foundation and access to 3-phase power (400–480V).

Water Circuit Integration: Install Y-strainer and expansion tank to prevent scale buildup.

Refrigerant Piping: Use brazed joints with nitrogen purging to avoid oxidation.

Startup Protocol: Pressurize to 150 PSI for 24 hours to verify shell integrity.

Maintenance Schedule:

Daily: Monitor inlet/outlet temperatures and differential pressure.

Monthly: Clean condenser coils with soft brush; inspect gaskets for leaks.

Annually: Replace desiccant filters and perform hydrostatic testing (300 PSI).

Standard Accessories:

Control Panel: IP65-rated with HMI touchscreen for real-time efficiency monitoring.

Pump Packages: Vertical multistage pumps with VFD integration.

Customization Options:

Material Upgrades: Titanium shells for ultra-corrosive environments (e.g., geothermal plants).

Noise Reduction: Acoustic enclosures with soundproofing rated to 65 dB(A).

Cold Storage Kits: Pre-insulated piping and glycol mixture optimization for -40°F applications.

Technical Support: Multilingual engineers available via email/phone (24-hour response SLA).

Spare Parts: 95% of components in stock; 48-hour shipping to major ports.

Warranty: 3-year base warranty + optional extension to 5 years.

Training: Free online modules for system operation and troubleshooting.

Previous article:No more.

The next one:No more.

Phone

+86 180 1742 6215Tel

Shanghai XiangNing Electromechanical Equipment Co., LTD XML