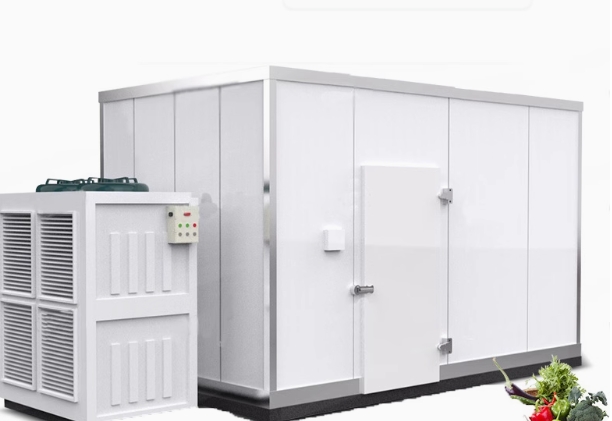

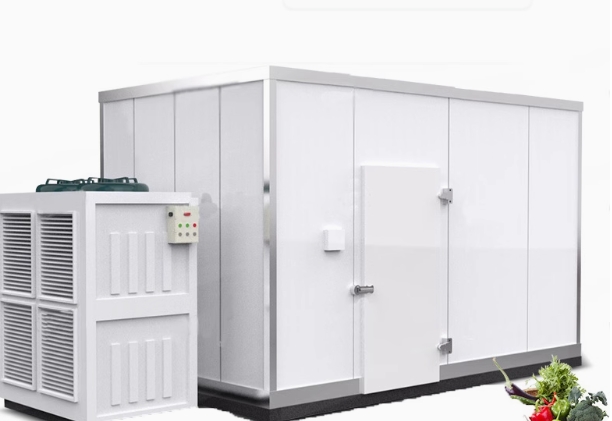

Walk-in cold storage offers modular solutions for medium-to-large cold chain needs. Using prefabricated sandwich panels for rapid assembly, it supports environments from -40°C deep-freeze to 15°C ambient. Integrated with smart temperature control and energy management systems, it suits food processing, pharmaceutical storage, and research applications.

Role

Food Industry: Meat processing, frozen food buffering

Pharma Sector: Long-term vaccine storage, plasma低温管理

3PL: Multi-temperature distribution hubs

Selling Points

✅ Rapid Cooldown: 30°C to -18°C in 90 minutes

✅ 30% Energy Savings: Inverter compressors + heat recovery

✅ Scalability: Add modules or chillers post-installation

Advantages

Compliance: Passed FDA/GMP dynamic validation

Safety: Dual-circuit power + emergency ventilation

Lifecycle Support: From design to end-of-life recycling

🔹 Free Consultation: 1-on-1 design with cold chain

experts

🔹 Case Studies: Real-world applications from

leading enterprises

Refrigeration System

Copeland/Bitzer compressors with smart defrost logic (activates at ≤3mm frost)

Electronic expansion valves: ±0.1°C precision, <0.5s response time

Construction

PU sandwich panels: ≤0.021W/(m·K) thermal conductivity, tongue-and-groove sealing

Flooring: XPS insulation + 304 stainless steel slip-resistant surface

Temperature Control

Siemens PLC: 4-20mA signal compatibility, WMS integration

Data Logging: 365-day continuous recording with USB/cloud backup

Installation Steps

Foundation Inspection: Verify floor levelness (≤2mm/m) and drainage slope (≥1%)

Panel Assembly: Use labyrinth seals to achieve ≤0.1m³/h@50Pa airtightness

Commissioning: Run 72h simulated full-load test, validate ±1.5°C uniformity

Daily Maintenance

Weekly Check: Condenser fin cleanliness (pressure drop ≤150Pa)

Monthly Test: Emergency lighting and alarm systems

Quarterly Service: Replace filter driers, check refrigerant purity (≥99.8%)

Standard Accessories

Crash Barriers: Hot-dip galvanized steel, 1.2m height

Rack Guides: Flush-mounted, 500kg/m load capacity

Viewing Window: Double-glazed electric heated glass (anti-fog)

Customization Options

Multi-Temperature Zones: Concurrent -18°C freeze and 2-8°C chill areas

Add-Ons: CO₂ backup system (for carbonated beverages)

Aesthetics: Corporate branding with RAL color paint

Service Commitment

Warranty: 5 years for compressors, 2 years for entire system

Response Time: 4h phone support, 48h on-site service (Mainland China)

Training: ISCEA-certified cold chain management courses

Support Coverage

Remote Monitoring: 4G/LoRa access globally

Spare Parts: 220+ countries via DHL

Preventive Maintenance: Annual deep service (pressure tests, leak checks)

Notes

Custom projects require 60-day lead time for design finalization

Overseas installations incur travel/visa costs

Post-warranty repairs charged at 85 RMB/hour labor rate

Previous article:Mobile shelf cold storage

The next one:Mobile medicine cold storage

The Latest in Energy-Efficient Refrigeration Systems for Cold Rooms

Cold Room Installation Guide: From Design to Completion

Phone

+86 180 1742 6215Tel

Shanghai XiangNing Electromechanical Equipment Co., LTD XML