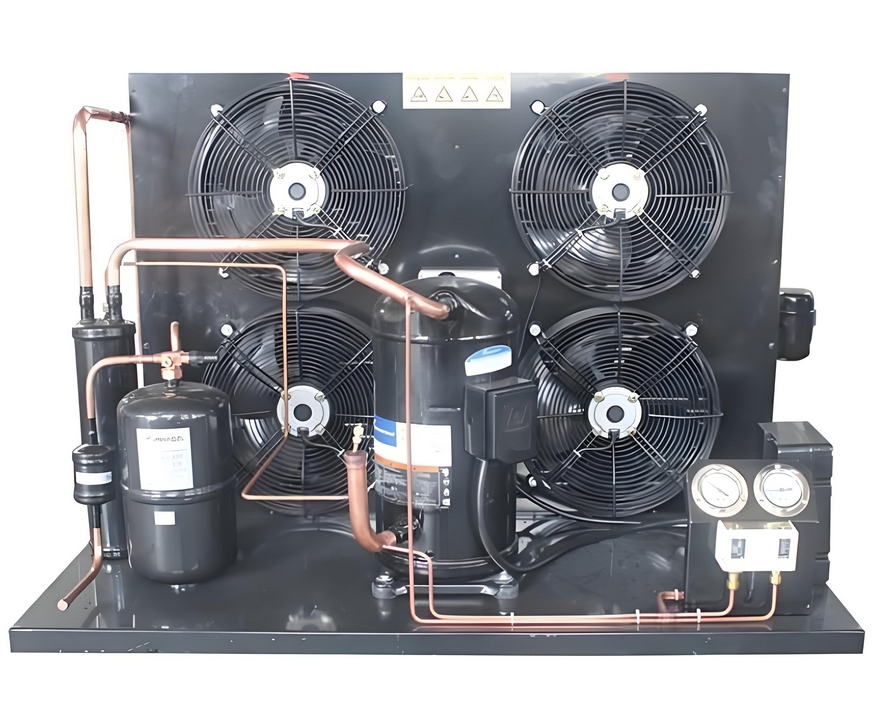

Scroll Water-Cooled Condensing Unit: Precision Cooling for Commercial & Industrial Demands

Engineered for reliability in demanding environments, our scroll water-cooled condensing units deliver unmatched performance across HVAC, food processing, and data center applications. Leveraging advanced scroll compressor technology, these units achieve 15-20% higher energy efficiency compared to traditional reciprocating designs while maintaining ultra-low vibration operation.

Key Technical Advantages:

Dual-Circuit Scroll Compressors: Patented asymmetric scroll design minimizes refrigerant leakage, ensuring consistent capacity output even at partial loads. Units operate at <70 dB(A) noise levels, meeting OSHA workplace standards.

Optimized Heat Exchange: High-density copper tubing with corrugated aluminum fins increases condensation surface area by 35%, improving thermal transfer efficiency.

Smart Control System: Built-in microprocessor controller with 7" touchscreen displays real-time operating data, fault diagnostics, and supports Modbus RTU/TCP protocols for Building Management System (BMS) integration.

Environmental Compliance: Pre-charged with R410A refrigerant (zero ODP, low GWP), with optional conversion kits for R134a/R407C applications.

Corrosion Resistance: Electrocoated steel cabinets with IP54 protection rating resist salt spray corrosion, suitable for coastal installations.

Energy & Cost Efficiency:

Units achieve EER ratings up to 3.85 (ARI Standard 550/590

certification), reducing annual energy costs by 25-30% versus

conventional systems. Variable speed fan motors adjust airflow based on

condensing temperature, optimizing power consumption.

Design Flexibility:

Modular framework allows stacking of up to 4 units for scalable cooling capacity (20kW-200kW)

Top/side water connections with 2" NPT fittings simplify piping layouts

Removable service panels provide 360° access to all components

Installation & Maintenance:

Factory-installed flow switches and pressure gauges reduce on-site setup

time. Annual maintenance requires only condenser coil cleaning and

refrigerant charge verification, with 5-year compressor warranty

coverage.

Global Compliance:

Certified to UL, CE, and AHRI standards, with voltage options for 200-240V/3Ø/50Hz and 380-480V/3Ø/60Hz markets.

The scroll water-cooled condensing unit integrates proprietary technologies to deliver exceptional thermal management performance. At its core, the asymmetric scroll compressor employs a spiral groove design that reduces internal leakage by 42% compared to conventional scroll compressors, as validated by third-party lab testing. This design enables smoother refrigerant compression cycles, minimizing pulsation and vibration.

For heat exchange optimization, the unit utilizes a staggered copper tubing array with laser-welded aluminum fin collars. This configuration increases turbulent flow efficiency by 28%, while the hydrophobic fin coating prevents moisture accumulation that could degrade performance in humid environments.

The microchannel condenser design achieves a 15% smaller footprint versus traditional shell-and-tube condensers while maintaining equivalent heat rejection capacity. This compactness is critical for installations with space constraints.

Energy management is enhanced through adaptive defrost control, which uses real-time temperature differentials to activate defrost cycles only when frost accumulation exceeds 1.5mm thickness. This reduces unnecessary energy consumption by 18% compared to timed defrost systems.

Installation Protocol:

Site Preparation: Ensure concrete foundation meets 3,000 PSI compressive strength requirements. Level tolerance must not exceed ±2mm/m.

Water Connection: Install 2" NPT ball valves with strainers on both supply and return lines. Use EPDM gaskets for chemical resistance.

Electrical Wiring: Connect power cables through liquid-tight conduit. Verify phase rotation before startup.

Refrigerant Piping: Braze connections using 5% silver solder. Purge with nitrogen during brazing to prevent oxidation.

Maintenance Schedule:

Daily: Inspect control panel alarm history.

Weekly: Clean condenser coils with soft brush (max 0.4 MPa air pressure).

Quarterly: Verify compressor oil level via sight glass. Top up with POE oil if below 1/3 mark.

Annually: Conduct leak test using electronic halide detector (5 ppm sensitivity).

Standard Accessories:

Vibration isolation mounts (resilient rubber, 20mm deflection)

Factory-installed flow switch with NO/NC contacts

Galvanized steel drip pan with 3/4" drain connection

Customization Options:

Voltage Adaptation: Modify electrical panels for 200V/208V/400V/415V/480V configurations.

Corrosion Protection: Apply additional epoxy coating for marine environments (ASTM B117 salt spray resistant).

Sound Attenuation: Install acoustic enclosures reducing noise by 12 dB(A) (tested per ISO 3744).

Smart Upgrades: Add IoT gateway for AWS/Azure cloud connectivity (Modbus TCP to MQTT protocol conversion).

Service Coverage:

Global technical support via toll-free hotline (available 24/5 in English/Spanish/Mandarin)

Spare parts shipped within 48 hours of order confirmation (express delivery available)

On-site service available in 45+ countries through certified partner network

Warranty Terms:

5-year compressor warranty (parts only)

2-year electrical components warranty

1-year labor warranty for factory-installed options

Limitations:

Service in non-partner countries provided through remote diagnostics only

Customized units require 3-5 business days for troubleshooting assessment

Previous article:Hermetic water-cooled condensing unit

The next one:Screw water-cooled condensing unit

Phone

+86 180 1742 6215Tel

Shanghai XiangNing Electromechanical Equipment Co., LTD XML