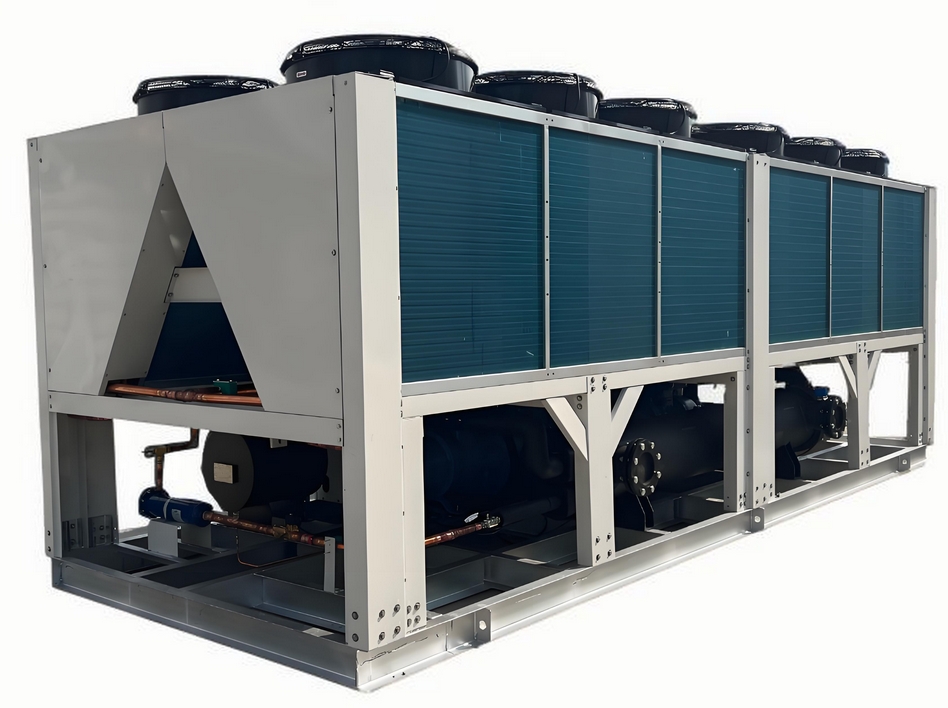

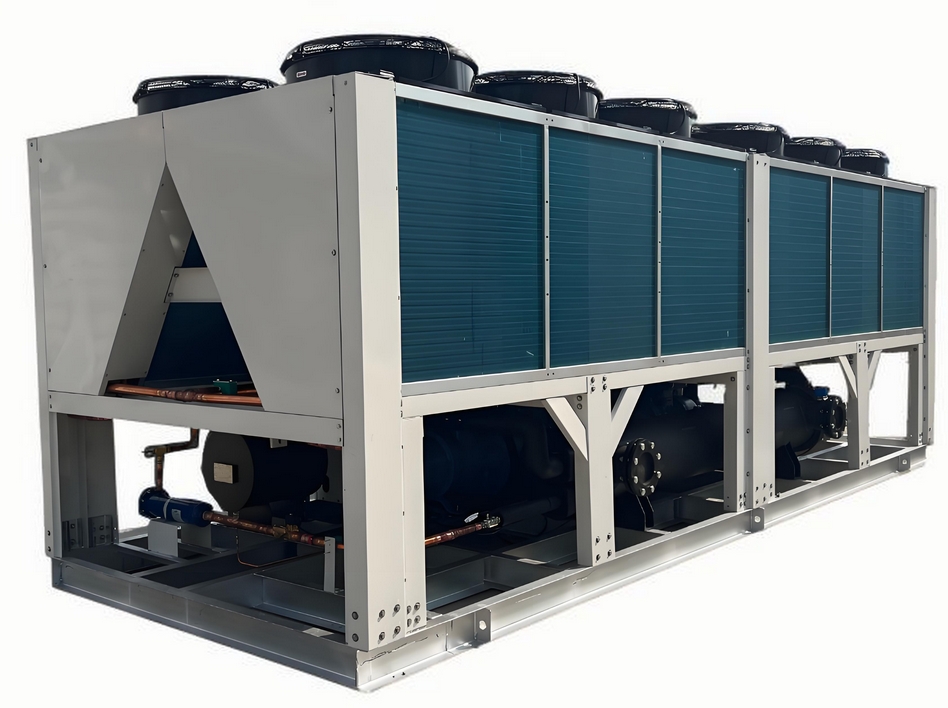

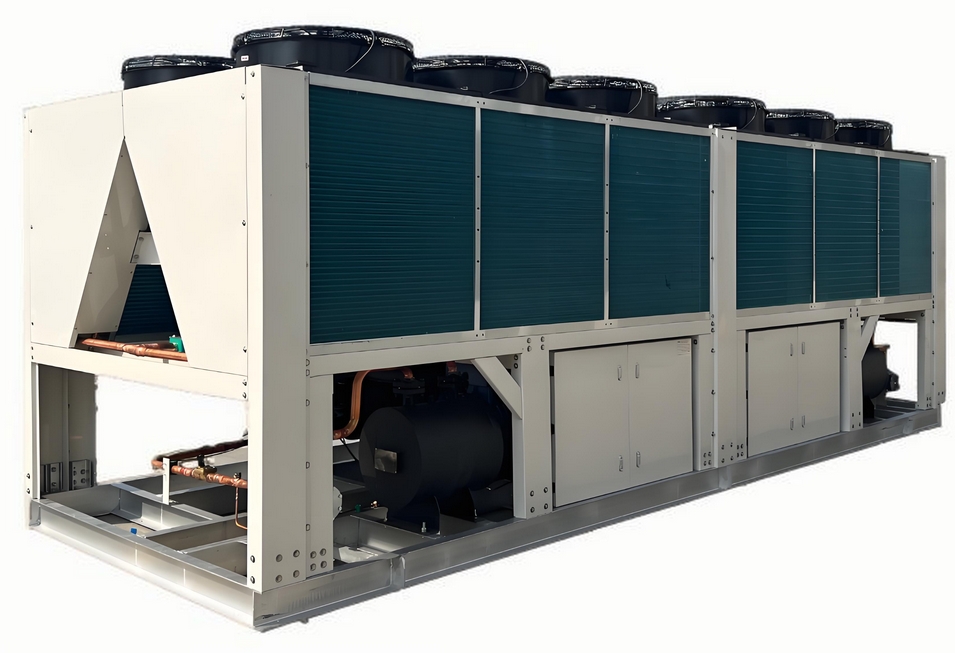

Industrial Air-Cooled Condensing Units – Precision Engineering for Commercial Refrigeration Excellence

Engineered for demanding applications in food processing, cold storage logistics, and pharmaceutical preservation, these units feature aerospace-grade aluminum alloy fins and internally threaded copper tubes to enhance heat exchange efficiency. The semi-hermetic screw compressor with slide valve capacity control achieves 25–100% uninterrupted modulation, delivering 18–22% energy savings versus conventional models.

Technical Depth:

Energy Efficiency: CFD-optimized axial fan arrays with variable frequency drives (VFDs) improve EER by 30% under partial loads, meeting EU ERP Lot 21 directives.

Environmental Robustness: Phase-loss protection and voltage fluctuation compensation (±15% tolerance) ensure stability in unstable power grids.

Serviceability: Full-access panel design enables 15-minute component access, with pressure gauge windows reducing inspection time by 60%.

Smart Connectivity: Embedded 4G module enables remote diagnostics and predictive maintenance, with fault alerts pushed to mobile devices.

Application-Specific Solutions:

Blast Freezers (-35°C to -40°C): Dual-compressor parallel systems for stepped temperature control.

Chilled Storage (-5°C to 5°C): Electronic expansion valves maintain ±0.5°C superheat accuracy.

Climate-Controlled Facilities (18°C to 25°C): Integrated humidity control modules.

Extreme Environments: Optional sandstorm filters and electric defrost systems.

Quality Assurance:

2,000-hour salt spray and -40°C to 80°C thermal shock testing for critical components.

48-hour factory burn-in under full load for every unit.

100% helium leak detection (≤5g/year leakage rate) for all welded joints.

Compressor Technology: Equipped with semi-hermetic screw compressors featuring slide valve capacity regulation, enabling seamless 25–100% load adaptation. Dual-stage compression design minimizes temperature fluctuations during defrost cycles.

Energy Efficiency Optimization: Integrates adaptive VFDs on axial fans and compressors, reducing power consumption by 18–22% under partial loads. Advanced algorithms adjust fan speeds based on real-time ambient conditions.

Thermal Management: Proprietary fin-and-tube geometry with hydrophilic coating prevents frost buildup in humid environments. Microchannel condenser coils enhance heat rejection efficiency by 15% compared to traditional designs.

Refrigerant Management: Dual-circuit refrigeration systems allow isolated operation for critical applications. Integrated liquid line filter-driers with sight glasses simplify maintenance and prevent system contamination.

Control Logic: PID-based microprocessor controller with Modbus RTU/TCP enables integration with building management systems (BMS). Alarm history logging and trend analysis tools aid predictive maintenance.

Site Preparation: Ensure 1.5m clearance around the unit for airflow. Level concrete foundation with anti-vibration pads required. Verify power supply compatibility (380V–480V/3Ph/50Hz) and install dedicated circuit breaker.

Refrigerant Handling: Charge with specified refrigerant type (R134a/R404A/R513A) using manifold gauge set. Verify superheat/subcooling values post-charge.

Startup Sequence: Initial 4-hour dry run to detect abnormal vibrations. Log compressor discharge temperatures and oil levels during break-in period.

Monthly: Clean condenser coils with soft brush; inspect fan blade alignment.

Quarterly: Test pressure switches and safety valves; lubricate motor bearings.

Annual: Replace oil filters; perform electrical insulation resistance test.

Troubleshooting: Flowchart-based diagnostic guide covers 12 common faults (e.g., low suction pressure, high head pressure). Includes pressure-enthalpy chart references for advanced users.

Standard Accessories:

Powder-coated steel frame with forklift slots.

5m pre-insulated refrigerant lineset.

Wall-mounted controller with 7-day programmable timer.

Optional Upgrades:

Environmental: Tropical kit (high-temperature fan motors, corrosion-resistant coating); arctic kit (crankcase heater, synthetic lubricant).

Safety: ATEX-certified explosion-proof motor; ammonia detection system.

Utility: Hot gas bypass valve; dual-circuit failover module.

Customization:

Voltage conversion (220V/60Hz available upon request).

Custom paint finishes (RAL color matching).

BMS protocol adaptation (BACnet/IP, LonWorks).

After-Sales Support

Technical Assistance: 24/7 multilingual helpdesk via email/phone. Remote diagnostics using embedded 4G module.

Warranty: 18-month comprehensive warranty (12 months standard + 6 months optional extension). Covers parts and labor for compressor failures.

Spare Parts: 95% parts availability within 48 hours (mainland China); 7–10 days for international orders via DHL/FedEx.

Previous article:No more.

The next one:No more.

Phone

+86 180 1742 6215Tel

Shanghai XiangNing Electromechanical Equipment Co., LTD XML